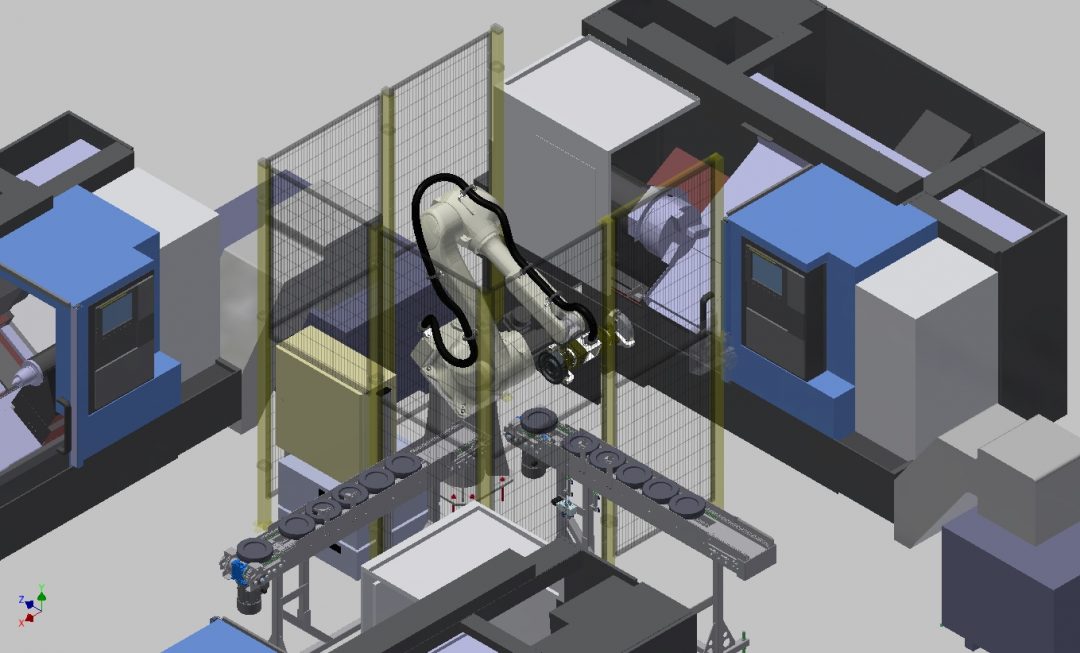

The concept assumed the preparation of such a position and the integration of the Kawasaki RS020N robot. Application: The operator places the forging on the conveyor belt, which is transported to the fenced working zone of the robot. There, it is possible to buffer up to 5 pieces of an intermediate. RS020N robot of the Japanese brand KAWASAKI using one of two three-fingered grippers grips the forging from the conveyor and, before pulling the finished part off with the second gripper, places it forging in the jaws of a CNC machine tool. The product is deposited on a conveyor belt leading it out of the robot’s working area in place, where it can be picked up by the operator for further processing.

Implementation of an automated CNC machining station for cast iron forgings